By Mike Shneer, CPD, Senior Plumbing/Fire Protection Engineer

We know that using the sun’s energy for heating is not a new idea. There is archeological evidence of solar heating in ancient Egypt, China, and the Roman empire. In the past century, roof mounted water tanks have been used as simple solar water heaters in many southern countries such as Thailand. Solar water heating / solar thermal technology has greatly improved during the past century. Modern solar thermal generation relies on the use of separate collector and storage components to increase efficiency.

UNGLAZED COLLECTORS

The unglazed solar thermal collector is the most basic type of collector. They do not have a coating or insulation. Unglazed collectors readily lose thermal energy to the environment where conditions are windy or cold and so are not suitable for year-round use in colder climates.

GLAZED FLAT PLATE COLLECTORS

Glazed liquid flat plate connectors utilize double layer glazing and insulation to reduce the amount of heat lost to the environment. However, a good portion of heat will still be lost on cold days due to insulation R-value. Due to the glazing and insulation, panels are solid which creates a greater wind load on the structure.

EVACUATED TUBE COLLECTORS

Evacuated tube collectors are the recommended technology for use in commercial and industrial applications where space is a concern. Evacuated tubes allow solar radiative heat gain, while insulating the hot water inside the tube from conductive heat loss into the atmosphere. Most evacuated tube solar collectors utilize direct sunlight and generate about 1000 BTUH per panel. The ROI with this technology has historically exceeded the life expectancy of the system by approximately 35 years. Additionally, there is a new, patented technology which can significantly reduce ROI.

COATED EVACUATED COLLECTORS

The SunQuest 250 Solar Thermal Collector has a proprietary patented coating on the tubes that allows for heat production from UV rays (even in cloudy weather conditions). These collectors generate approximately 18,000 BTUH per panel in a Northern U.S. climate vs. 1,000 BTUH per a typical panel. That is 18 times more BTUHs per panel. Panels are warranted for 10 years against 1″ hail and 150 mph winds.

SOLAR THERMAL SYSTEM LAYOUT

After being heated in the collector, solar heated water is pumped through a heat exchanger which can then be used to generate hot water for process, domestic, or space heating uses. The heat exchanger is used to heat a volume of water which can be used to account for usage peaks that do not coincide with production peaks. A full-size backup heat source (such as a gas fired water heater or boiler) is required to ensure hot water is available at times when the solar collector and/or solar storage tank capacity is low.

THERMAL STORAGE AND SAFETY

For residential, office or light commercial uses, peak solar thermal production often does not coincide with peak usage. The use of solar thermal storage tanks allows for the excess thermal energy produced during the middle of the day to be “saved” for use during peak usage times. For industrial or process applications with a more consistent usage, thermal storage is not as critical but is still required to account for any periods of downtime. As a means of protecting the solar thermal system from stagnating and overheating, an emergency heat dissipator is typically provided. A temperature and pressure relief valve is added as an additional safety device.

STRUCTURAL CONSIDERATIONS

For a best compromise to maximize year-round solar thermal energy production, panels should be installed at an angle equal to the latitude of the site. The weight of the panels – as well as the associated wind load – must be accommodated in the structural design of the roof supports.

FINANCIAL INCENTIVES

Financial incentives can help to reduce upfront costs and shorten the payback period.

Useful links for state specific incentives:

REBATES, LOANS, GRANTS, TAX CREDITS, DEDUCTIONS, EXEMPTIONS EXAMPLES

- Business Energy Investment Tax Credit (ITC) – DSIRE – The federal Business Energy Investment Tax Credit (ITC) has been amended a number of times, most recently and most significantly by the Inflation Reduction Act of 2022. That bill established new prevailing wage and apprenticeship requirements for larger system to qualify for the full 30% tax credit.

- Depreciation Modified Accelerated Cost Recovery System (MACRS) – The Modified Accelerated Cost Recovery System (MACRS) is the current tax depreciation system in the United States. Under this system, the capitalized cost (basis) of tangible property is recovered over a specified life by annual deductions for depreciation. The lives are specified broadly in the Internal Revenue Code.

- Utility Energy Efficiency Incentives- Local Utility Company

- Renewable Energy Fund Energy Rebate Program- State Public Utilities Commission (PUC)

- Solar renewable energy certificates (SREC)- State Public Utilities Commission (PUC)

SOLAR RENEWABLE ENERGY CERTIFICATES (SRECs)

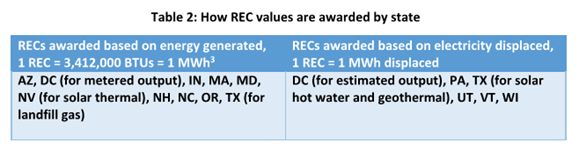

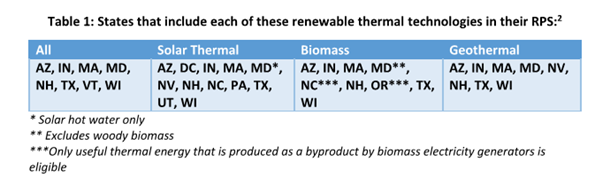

SRECs or RECs are a result of Renewable Portfolio Standard Policies (RPS). 30 States have RPS. Utility providers must create a certain percentage of total power through solar generation or buy RECs (Renewable Energy Certificates). NJ, for example, requires 50% of electricity through renewable sources by 2030. Some states specify a solar carve out requiring Solar Renewable Energy Certificates. Each SREC represents 1,000 kwh of power through solar generation. Some states allow solar thermal to participate in SREC markets, but most of the market is dominated by PV. 14 states allow Renewable Thermal including Solar Thermal, Biomass and Geothermal. Alternative compliance payments for non-compliance vary by state.

ACPs act as a ceiling for SREC market (Maryland- $60, DC-$500, NJ-$50, NH-$26). Requirements are unique to each state and not all states have an active SREC trading market.

Solar thermal may be awarded SRECs in some states (Maryland and North Carolina). Massachusetts offers Alternative Energy Credits for Renewable Thermal. New Hampshire is the only state to establish a separate carve out for Renewable Thermal Technology

MORE INFO ON RENEWABLE THERMAL

RETURN ON INVESTMENT (ROI) EXAMPLE

Example System Size: 38k s/f = approximately 500 panels

- RetScreen free calculation software is available at https://www.nrcan.gc.ca/maps-tools-and-publications/tools/modelling-tools/retscreen/7465

- Application: Continuous Process Hot Water Generation for an industrial site in Ohio

- Technology: Evacuated Tube technology by Solar America

- System Investment: approximately $4,000,000 (~$105/SF)

- Cost includes equipment, installation. Structural cost includes piping and controls

- Annual Production (MMBtu’s): approximately 40,000 est.

- Natural Gas Cost savings (@ $1.4 per Therm): approximately $575,000 per year.

- Project ROI (not including incentives): approximately 7 years.

- System lifespan: approximately 30 years.

- Federal Investment Tax Credits, Solar renewable energy certificates (SREC), and Carbon Credits further decrease initial Investment and ROI time frame.

- Ohio doesn’t offer SRECS or REC’s for solar thermal. Similar savings in MA for example would qualify for AEC’s with a potential value of $200,000/year improving the ROI to ~5 years (Not counting any other incentives/rebates)

- Higher / consistent year round usage = Better ROI

NV5 is a global engineering and consulting firm in both the private and public sectors. From infrastructure engineering to building design an ftechnology, our project portfolio demonstrates success in major market sectors around the world. The Buildings and Technology vertical of NV5 specializes in Building Solutions, Clean Energy, Owner’s Rep, Planning & Design and Technology Services. NV5 takes pride in helping our clients develop high-quality, cost effective, and sustainable project that deliver solutions and improve lives.

Mike Shneer is a Senior Plumbing / Fire Protection Engineer in NV5’s Andover, MA office. He has designed plumbing and fire protection systems for various types of buildings within the public and private sectors. He is responsible for the design of domestic water and waste systems as well as fire protection, acid/chemical waste, process gas, vacuum and compressed air systems for healthcare, commercial, industrial, laboratory, educational and institutional facilities. Mike can be reached at Michael.Shneer@NV5.com.